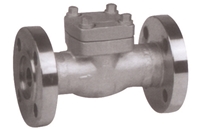

Check Valve

ANIX Check valves manufactured and distributed by ANIX Valve USA are made of Cast steel, CF8M stainless steel, 316 stainless steel, WCB carbon steel and Forged steel material which include Threaded 2 piece spring check valve 1000 WOG, Threaded 3 piece spring check valve 1000 WOG, Threaded swing check vlalve class 800, Flanged swing check valve and Wafer check with class 150, class 300 and class 600 available.

Summary of Check Valves

A check valve is a one way valve which means the flow can only go one way and stop one way. They are mostly placed in the outlet side of the pump, so it can make sure the pump does not get any backflow. They are mostly placed in hvac systems, in which hvac systems are placed in big buildings. It is cheap, effective, and easy to use. Have to make sure the valve is facing the right way, it will have an arrow on top so it can show you where the flow will be coming from. If it is installed wrongly the flow could back up and cause a lot of damage to the pump and the valve. For the valve to be open it has to have a certain amount of pressure flow coming through, that's called “cracking pressure”. The pressure could differ depending on the size and and the design of the valve. If the inlet pressure is not high enough for the outlet pressure then the valve shall close. The most common type of check valve is spring loaded in-line check valves. Where the flow has enough pressure so the valve can open. ANother valve type is spring loaded y it is the same as the spring loaded inline check. The only difference is the way the disc is placed, since it is more at an angle so it tends to be more of any shape. Another valve type is a diaphragm, it does not have cracking pressure. The diaphragm has a rubber diaphragm that flexes the inlet pressure to increase. A lift valve has a guided disc that lifts up from the seat allowing the fluid flow through.

Kinds of wafer check valves

The disc check valves are smaller than the standard swing valves and they cost considerably less. These valves usually have four parts and they are body, disc, spring and a spring retainer. The design of these wafer check valves is another advantage apart from the size and cost. It is because of this design; these valves can be installed in any position. For instance, they can be fitted even in the vertical pipelines where the liquids flow downwards.

Swing type wafer check valves

These valves are usually similar to that of the standard swing valves. Here the valves do not have full body like others, so when the valve opens up, the flap is required to move in to the top of the pipeline. In order for this work, the flap has to be designed with smaller diameter than that of the pipe. Because of the pressure considerations, the swing type wafer check valves are usually used only in larger size pipelines.

Applications of wafer check valves

The widespread usage of the wafer check valves is because of their compact design and lower prices. These valves are becoming the most preferred check valves nowadays. Some of the applications of these valves are given below:

- Boiler feed lines

- Steam traps

- Hot water circuits

- Vacuum breakers

- Blending operations

- Pipeline fitting protection

- Multiple boiler applications

- Blow down vessels and

- Flash vessels

Function of duo check valve

The function of the duo check valve is dependant on the two check valves. The check valve may be defined as the mechanical device which allows the flow of fluid in only one direction. These check valves are typically two port valves as they have two openings in them; one for the fluid to enter and the other one for the fluid to leave. A ball valve or a gate valve is installed at both the ends of the duo check valves for the purpose of separation or testing. Usually, very small ball valves are fitted in this position in order to fasten the testing equipment. This is done to test whether the duo check valves are still functional.

Applications of dual disc wafer check valve

The dual disc wafer check valve can operate at two separate conditions very effectively. First of all, during the normal flow of the fluid through it, the spring loaded check valve is opened in order to let the fluid flow. On the other hand, during the reverse flow, the spring loaded check valve closes in order to arrest the flow of fluid. As far as the applications are concerned, the duo check valve assemblies are very much appropriate for back siphonage and the back pressure related functions. But these valves are not preferable for the highly hazardous applications. The most common and general usage of the duo check valve is in fire sprinkler, lawn irrigation and for the use in combi boiler systems.