Anix Valve USA is a manufacturer of industrial valves based in Houston, Texas. For more information, please visit https://anixusa.com/

The manual valves can be operated with the help of a hand wheel, lever or pedal. But the automatic valves are operated by the changes in the pressure, temperature or volume of the fluids. These differences trigger the piston or diaphragm and which then activates the valve. For instance, the safety valves found in steam boilers or hot water systems are automatic industrial valves. Some of the complex control systems in the industry also require valves and they cannot alone control the flow, based on the external input. So for this purpose these systems require an actuator. This actuator will knock the valve based upon its inputs and this in turn helps the valve to be set in an appropriate position.

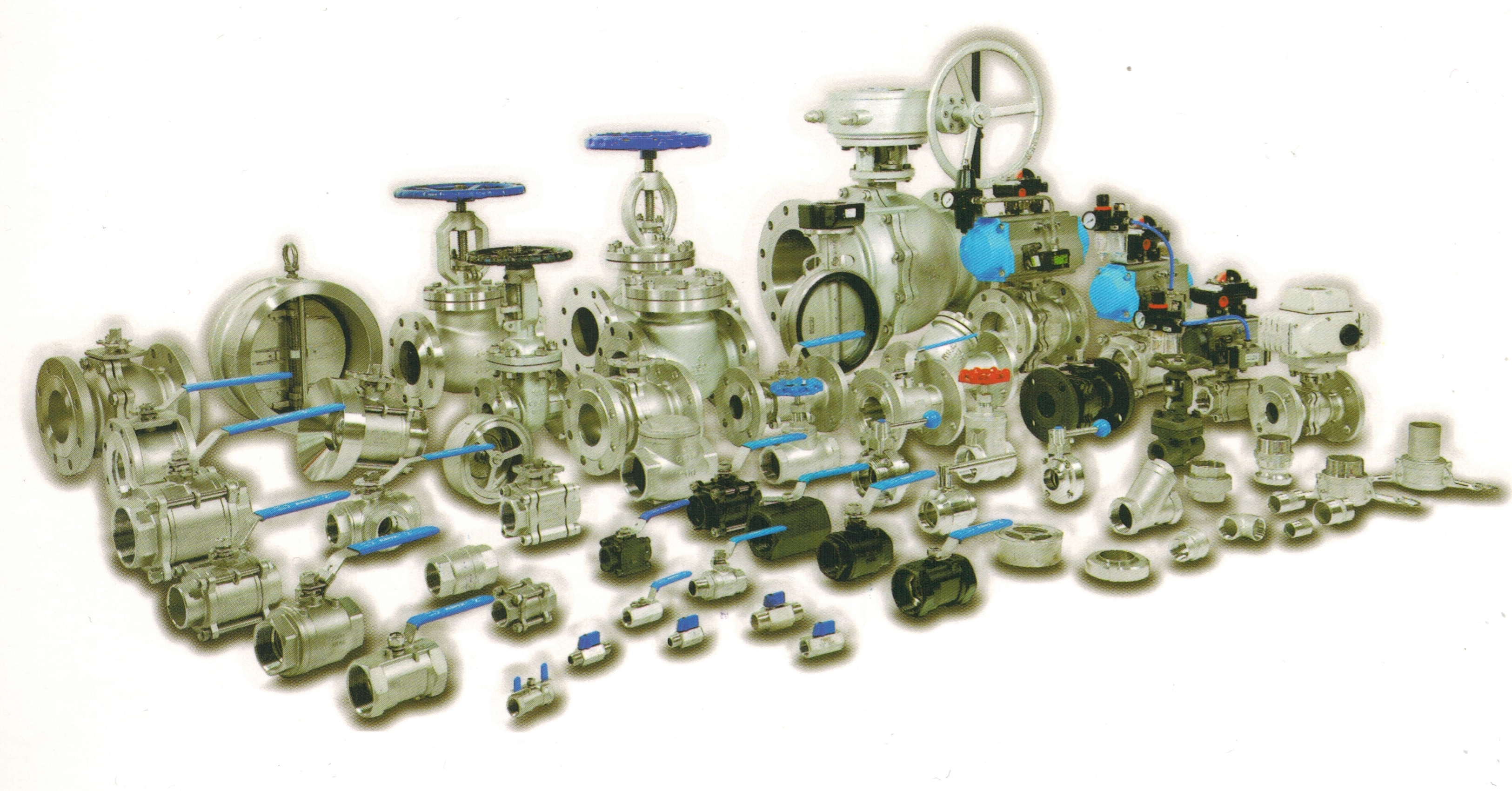

Different types of industrial valves

The classification of the different kinds of industrial valves has to be based on two different criteria. The first criterion is the variation in their designs and the second one is based on the differences in their operation. Some of the common kinds of valves that are differentiated based on the first criterion are gate valve, poppet valve, check valve, butterfly valve, ball valve and pinch valve. The valves that are classified based on the operation are manual valves, solenoid valves, hydraulic or pneumatic valves.

Any kind of valve usually has the following important parts. They are body and bonnet which form the main casing of the valve and ports which allow the flow of fluid in and out of the valve. Other parts may include seat, stem, spring and valve ball.

Advancements

Some of technical advances have touched these manifold valves too and have in turn resulted in more sophisticated valve systems for the use of various industries. For instance, one such advancement is the manifold valve with two separate valves in which it enables the operation of one valve while it disables the operation of the other valve. Such a manifold valve will have a main passageway, a subdivision passageway diverging from the main one and valve openings and closings for both the passageways.

Needle valves are used in flow metered purposes and have their significance in regulating the flow of the liquid in such cases. These are extremely useful when the flow rate is needed to be less and the rate of flow of the fluid or the liquid is desired to be at a constant rate throughout for optimum usage of the respective application.

Needle valves are unsuitable for simple shut down applications as they require many turns of the screw that is prevalent in the valve for the flow to be kept at a desired level required for the particular application. Sometimes the small needle valves have their usage in the water heating applications. In this context they are used as bleed valves. It is very difficult to say whether a needle valve is open or shut. The particular position of the handle of the needle valve and its examination is not adequate to conclude that such a valve has been kept open or it has been closed. In case of other valves the position of the handle or the rising stem is enough to come to the conclusion that the relevant type of valve is open or shut. In this case however caution has to be exercised to ascertain the position of the valve.

The standard control oil valves are used extensively in thousands of applications all over the world. Everyday, the design of these valves gets simpler and simpler and facilitates the straightforward use of maintenance procedures, reduction in operation time and are available at low costs. Many of the world class parts production industries have invested their time, resources, talented staffs and money hugely for creating more sophisticated designs of oil and gas valves that can be used widely fields. This increase in production capabilities is attributed to the ever growing demand for these valves among the various industries. Some advanced abilities like thermal resistance, cast valve body, improved opening and closing are found in the newer valves.

Applications of oil valves

First of all, the oil valves can be used in the petrochemical and other refinery plants for the regulation of oils. Other applications of these valves may include water treatment plants, sewage plants and power generation plants as well.