By: Lauryn B.

Anix Valve USA is a valve manufacturer based in Houston, Texas. Find out about our wide selection of butterfly valves at https://anixusa.com/butterfly-valves-2

What is a butterfly valve?

A butterfly quarter is a quarter-turn valve, allowing for a quick shut off making it cost efficient. The “butterfly” is a metal disc positioned in the center of the pipe with a rod passing through the disc to an actuator on the outside of the valve. It is in the shape of a gear, that is usually referred to as a gearbox, while the handwheel is connected to the stem. Rotating the actuator turns the disc either parallel or perpendicular to the flow. The valve is fully opened or closed when the disc is rotated a quarter turn, to stop, regulate, or start the flow. They are suited for handling large flows of liquid and gas at low pressures.

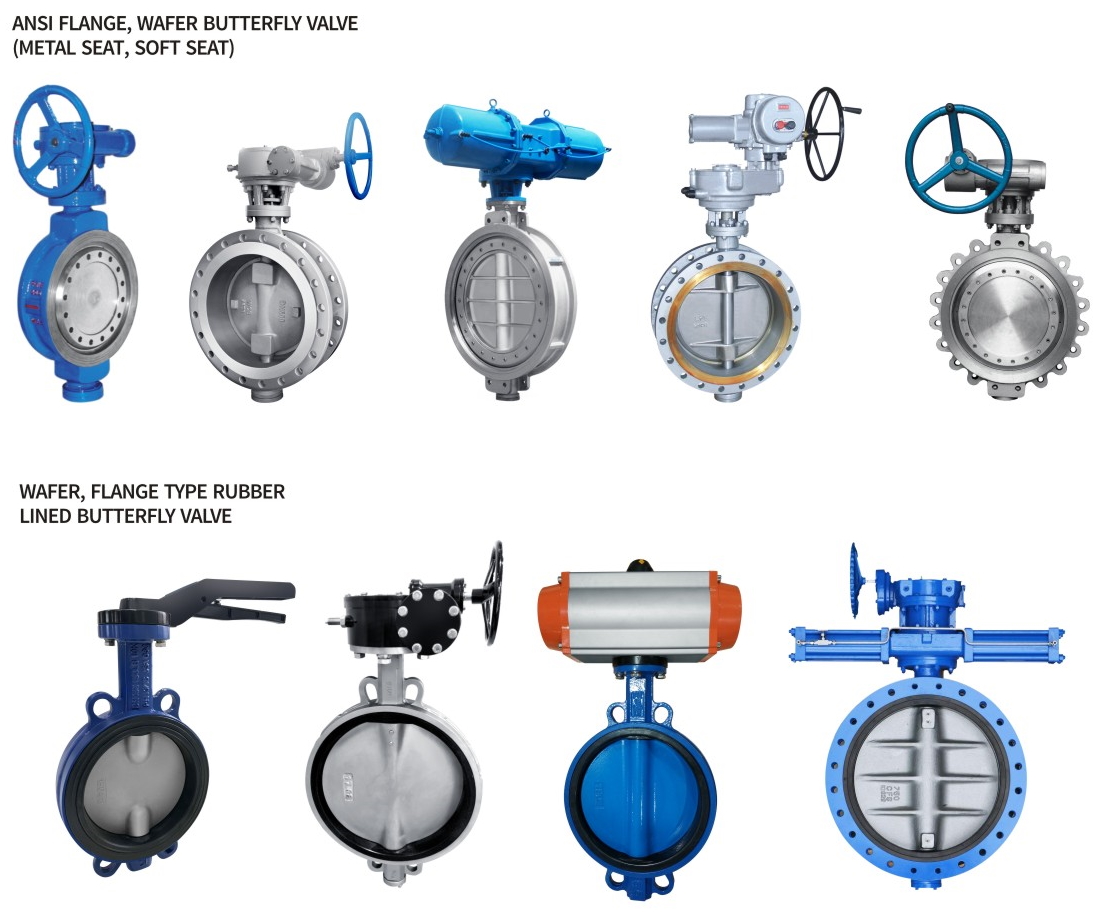

Types of Butterfly Valves

The most common body types of the butterfly valves manufactured are short, circular body, a round disc, metal-to-metal or soft seats, top and bottom shaft bearings, and a stuffing box. Each design for the valve varies depending on the use. One type is the wafer type that fits in between 2 flanges. Another type is the lug wafer type, where it's held between 2 flanges by bolts, and that pass through the valve casing. They are an advantage to the gate, globe, plug, and ball valves, since the maintenance cost to fix is low and there are a lot of moving parts which allow any fluid to flow freely.

Advantages of Butterfly Valves

It's used for different fluid services and is best in slurry situations. One advantage is that it is compressed so it doesn't need a lot of space , compared to the other valves. It's not heavy, it's lightweight. It's quick to use the handle and it does not require a lot of time to open or close. It is audible in different sizes, from small to very large. It also has a low pressure drop but a high pressure recovery.

Actuation method

Butterfly valves come in various operated handles, such as manually by handles and gears or automatically by electric, pneumatic or hydraulic actuators. Manual actuations are easy to operate and inexpensive, and are made as either a hand lever or a gear. The handlebar is the most common of butterfly valves and is capable of being open, partially closed, and fully closed. The gears are designed for much bigger valves, in which it increases the torque but decreases the speed for the opening and closing of the valve. These are self locking, and have position indicators. Automatic actuations are the most reliable since you can use it in any remote location. It is designed to fail open(it stays open if actuator fails) and or fail closed ( it stays open if actuator fails). One type is electric which uses an electric motor at the stem. Another is pneumatic which compresses the air so it can open and or close. And lastly, there is the hydraulic which uses a hydraulic pressure to move a piston or diaphragm to open/close the valve.

Butterfly valve vs ball valve

Butterfly valves are cheaper, easier to install, and is a small installation footprint compared to ball valves. Butterfly valves don’t have a complicated design so they don't have a lot of moving parts which means it is easier to repair and cheaper to produce. But, butterfly valve discs can not be cleaned due to their position and location. Ball valves are more suited for high pressure small applications, since they don't cause a lot of pressure to the system.