By: Jillian Chisefsky

Anix Valve USA is an industrial and fittings manufacturer for importers, distributors, and OEM customers. Anix has a proven track record of delivering high quality, reliable and effective products along with personable customer support, a team of technical experts, competitive pricing, and proper certifications. Trusted since 1988 to meet the needs of a wide range of industries including oil, gas, electricity, biology, pharmaceutical, textile, fiber, military, water supply, commercial plumbing and more.

Table of Contents:

Choosing the Right Control Valve Manufacturer

Quality

Consider a control valve manufacturer based on their high quality and reliable products. Quality control valves start with basic product design and the sourcing of raw materials, to the manufacturing process, product testing and certifications. Also take into consideration the manufacturer’s quality of customer service and reputation.

What determines quality?

Materials: The raw materials used are high quality and durable to ensure the longevity and reliability of the final product. Anix uses premium quality materials such as carbon steel, stainless steel, brass and cast iron.

Testing: Testing may include performance, durability, safety, and compliance testing. Testing is used to ensure the products are not only safe to use, but they perform correctly, are durable and comply with industry standards.Anix ensures the quality and safety of its products by performing these tests.

Design: Design factors include functionality, ergonomics, durability, simplicity, aesthetics, and innovation. Anix designs products with the end-user in mind, ensuring the preferences and needs of the customer. Anix makes sure the design is durable and adheres to wear and tear during long-term use.

Quality Control: Quality control includes material and component inspections, process control, and product inspections. Anix inspects the raw materials used to create the product to ensure they meet high standards; there are strict procedures used to monitor and control each manufacturing process.

Continuous Improvement: The manufacturer strives to create and provide products that satisfy customer needs and expectations. Anix regularly reviews its products and services by taking customer feedback, adopting the latest technology, and providing ongoing training and development to employees.

Product Variety

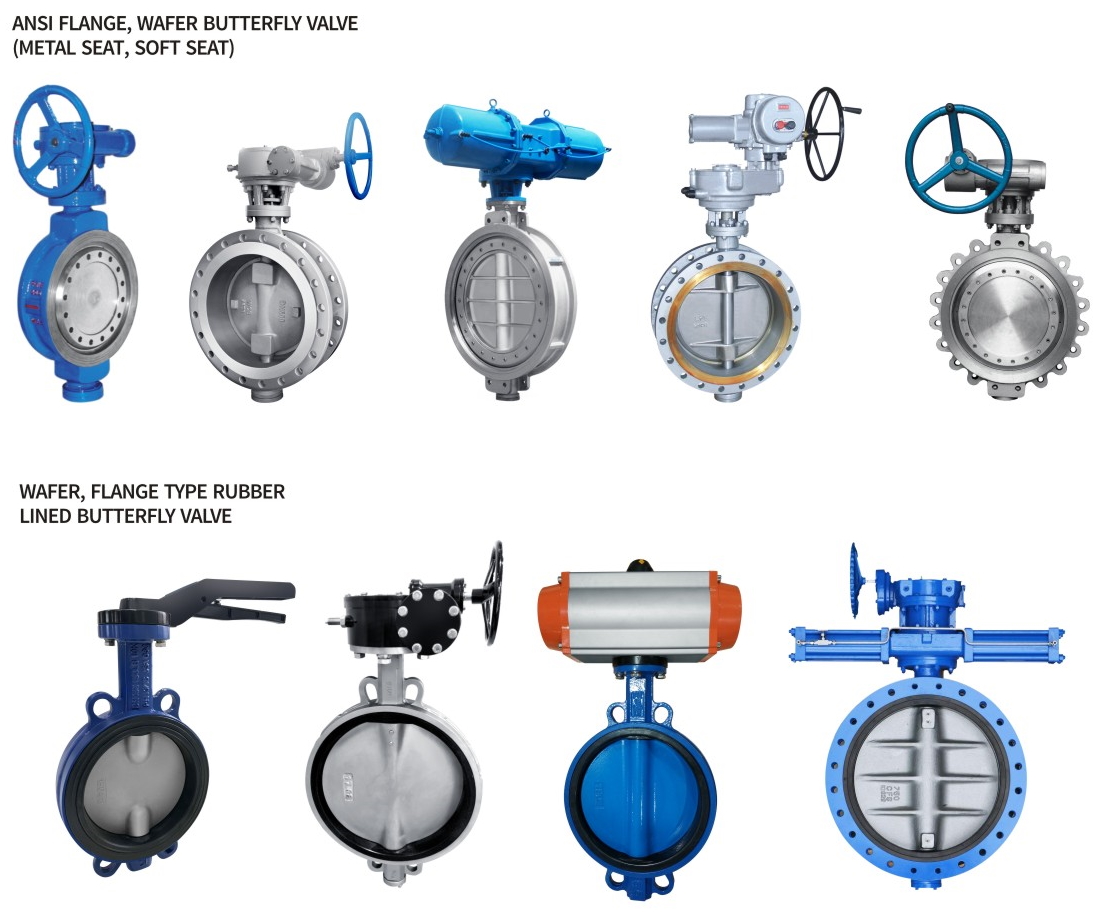

A good manufacturer will offer a wide array of products. There should be a range of valves to meet various application requirements and industry needs.

Anix Valve USA offers control, ball, gate, globe, check and trunnion valves, Y strainers, pipe fittings and more. Anix can meet the diverse needs of customers by offering several categories of products such as electrical, security lighting and HVAC valves.

|

|

|

|

Full Product list could be found here

Cost

Find a manufacturer that gives you the best value for your money. Anix offers competitive pricing for its customers, making an affordable option for those looking for a cost-conscious solution.

Manufacturers should have:

Lean manufacturing: Focusing on limiting waste through the manufacturing process while still maximizing efficiency. This helps reduce the costs of product without trading off quality.

Strategic Sourcing: Carefully source raw materials from trusted and reliable suppliers at a favorable cost to ensure the product is affordable.

Economies of Scale: Companies can reduce the cost per unit by producing a high volume of products at one time. Because of this, Anix customers could save by buying in larger volumes.

Automation: Using advanced technology to push efficiency in the workplace and continuously improve work processes.

Industry Standards

Look for manufacturers that meet relevant industry certifications, such as API, ISO, ASME, and NACE. Industry standards and certifications are crucial for a manufacturer to provide high quality products that are safe, perform well and can withstand wear and tear.

Some Key Certifications for the Control Valve Industry Include:

API (The American Petroleum Institute): Widely recognized as the benchmark for high quality and performance of the oil and gas industry.

ISO (The International Organization for Standardization): An international quality recognition system that ensures a company can meet customer needs properly.

ASME (The American Society of Mechanical Engineers): Sets the standards for pressure vessel design, construction, and inspection.

NACE (The National Association of Corrosion Engineers): Standards for protection from corrosion.

Click for full Anix USA certification List

Technical Expertise

The manufacturer should have a team of advanced expertise for proper technical support to help with choosing the right valve for your needs and helping you after the sale. They should create a customer relationship ensuring that you are satisfied with their product.

Anix has a team of expertly trained engineers and staff that will provide knowledge of design, function, and repair of products for the electrical, lighting, HVAC and many more industries. The team is knowledgeable of the latest technological and industry trends. The company invests in intellectual research and development to stay on top of competitors and constantly improve the quality of their products.

Availability

Consider the convenience of the manufacturer. You want one that will have your item in stock and deliver your order on time. Choose a manufacturer that will adhere to your desired timeframe.

As a globalized brand, Anix provides products and services through a number of distributors around the world. Products are readily accessible to customers with reliable delivery and after sale support. Anix provides quick response time to customers looking for help.

Customer Service

Find a manufacturer that offers support from choosing a product to installation, maintenance, and repair services. The manufacturer should be personable and available to assist your every need.

Anix USA is committed to offering exceptional customer service that includes product training, maintenance, customization, warranty, quick response time and support after the sale. Anix ensures that customers get the value for the cost by providing these extra services before and after the sale.

Read our blog to learn more about Anix and our product offers