By Lauryn B.

Anix Valve USA is a manufacturing company based in the United States. Contact us today at https://anixusa.com/ContactUs to find out about the wide range of valves and fittings that we carry!

With a wide range of stainless steel and cast steel valves available, Anix is primed to serve its customers. The company is looking for its stocking distribution partners.

Introduction

Have you ever wondered how and why valves are made, processed and then delivered to your door? Well, that’s what I’m here to tell you. Valves are important items used in our everyday life. Without it we wouldn't have things such as heat or water. Valves are used in the basic mechanical functions in our life. It’s essential for all manufacturing processes and every energy production and supply system. There are various steps to make the right valve function for your needs. The basic steps for it to be functionally ready are the design, plastic moulding, mechanical processing, assembly and testing, and quality. The process for it to be manufactured is a complex and long process. It needs to be manufactured for perfect efficiency, and undergo various tests so it's in perfect functioning order befitting our customers.

Did you know that all the supply pipeline systems we rely on so much would be faulty without formidable valves? Read on to discover facts behind the making of industrial valves.

Valves control the flow of liquid or gas in the various supply system. For instance, a valve controls the water flow in your kitchen sink and shower! For steady and efficient supply, industrial valves are used by gas, water, and oil supply utilities. Industrial valves must be built to withstand high pressure. These valves must also be high-quality to withstand years of service and exposure to extreme environments. The manufacturing process of industrial valves is a complex process that requires great care to deliver quality continually. This article contains details on the production process and methods used.

Manufacturing Checklist

The manufacturing department will find the necessary materials needed to cast the valve best suited for your needs, such as the materials needed to build the valve and the type of material to design the casting of the valve. Will also look for the raw materials needed to build the valve such as the stem, spool, body, disc, and bonnet, making sure that the materials are compliant. After getting all the materials the team will go over the checklist to make sure everything is done and complete, and to have the final draft of the design completed. Once the design is completed and finalized, it’s time to manufacture them. There are 2 common methods that are used to manufacture the valves, the cast method and forged method.

When all the materials are available, the production process begins. A valve has four components: The stem, body, spool and bonnet. All these parts are made independently. The company employs either the casting or forging method in production.

Cast methods and Assembly

Before we start with the cast methods, we would have to create the ideal valve shape. Once you have defined your ideal valve shape, you print out multiple copies of the pattern using your computer’s laser printer. You then cut out each separate part using tin snips or razor blades. The various parts from this initial step are finally put together to form the finished check pump.

This formation method produces an exact copy of the designed pattern. However, it is slower than other methods, so for small runs (50-100 pieces) wire forming is recommended. For larger quantities (1000+ pieces), flexible manufacturing is still preferred over the printing and cutting approach. Weighing is one of the most important parts of producing check valves. This helps determine their strength and how much pressure they can withstand before failing. You may notice that even with the same opening, some will be heavier than others. This is because the lighter ones are often made of cast iron while the heaver ones are light metals.

The cast method body is when the pre-shape is cleaned, the body is put on the turning machine, so the single cutter can cut the desired shape needed. Then a coating material is added over the entire body. Then the next step is to polish the whole body, create the threads over the body, so attachments can be installed to the body. Each hole would be a different size depending on the valve size requirement. Then it’s painted and baked with elastomer. For the seat, it goes through the same process as the body. It needs to be aligned perfectly to the body. The stem does not need a lot of manufacturing, it just needs to be cut into the right dimensions.

After choosing the material, it is cut into a specific length and width. Then it’s forged, each body is heated to a certain degree then the excess material is trimmed from the body. While it’s still hot, it’s molded into the correct shape and then sandblasted, which makes the valve smooth and clean. Machining enhances the size and thread and shapes depending on the design of the valve.

When all the materials are ready, then it is time to put them all together. The technicians attach all the components together by hand.

Product Testing

Then when everything is ready it undergoes the testing stage to make sure it works and there is no leakage when the fluid goes through. It could range from a couple hours to a day, depending on the valve size. If there is leakage, it’s repaired so it works correctly, otherwise the valve shall move onto the next step, to see if it can handle water pressure. If it can withstand the high pressure, then it passes the test and is ready for the last phase.

After the product passes all the tests, the QA inspector checks the valves for leaks and to make sure there are no production errors. Quality assurance personnel conduct a thorough inspection of the valves to identify deformity, leaks and other possible production errors. Once the valves pass this stage, they can be released to the customer. This last inspection is to make sure the quality of the product meets the company’s standards. The product is now ready for consumers to purchase and use.

At this stage, experts fill the valves with 6-8 bar pressure for a few hours a day. If any leaks are detected, the valves will be repaired. When all valves pass the pressure test, they proceed to the next stage.

Bringing it to the Consumer

When the company receives an order from the customer, they will discuss and agree on the design and price. Once an agreement is made, the company begins creating the valves by gathering the required raw materials. The manufacturing team does a countercheck to confirm that all materials required are available. The materials must be high-quality.

The customer can view our catalogue and based on the design and function required, choose the one that best fits the criteria needed for the job. Using our webpage, click on the product and it will give you the information of the product such as the material it’s made from, specs, and a downloadable information sheet. Join now to get the benefits our company offers.

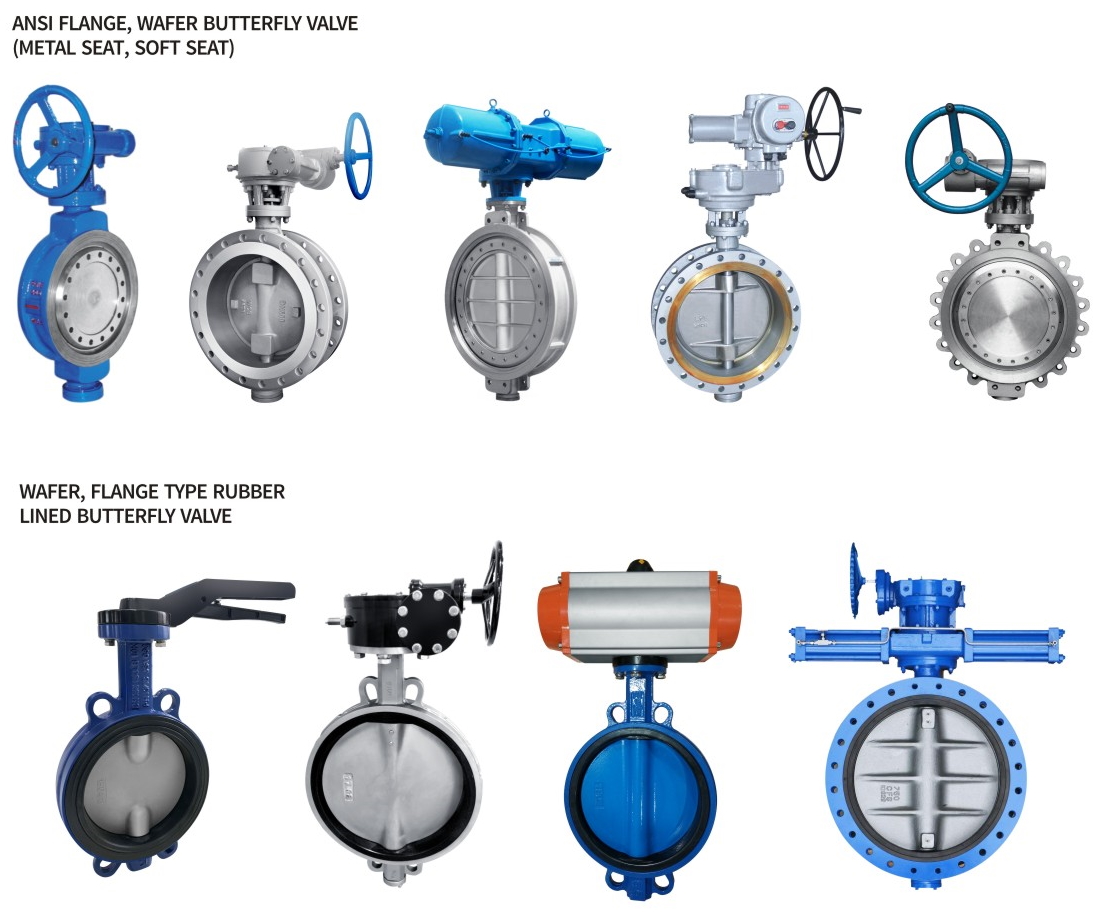

Anix is a Top Supplier of Valves in the United States. Below are the variety of products Anix offers:

1. Ball Valves

2. Gate Valves

3. Globe Valves

5. Check Valves

7. Actuators, Fittings, and many more

What Are Industrial Valves?

Industrial valves are devices used to control the flow of water, gas, oil or slurry. Plumbers fit industrial valves in strategic points along the pipeline supply chains to control the flow of materials.

The valves regulate the flow of substances by opening, closing or causing a partial obstruction.

There are different types of valves depending on the application. The types include butterfly, globe, gate, check and ball valves.

Without valves, our supply systems would be a mess. We would experience endless cases of spills and blockages within different supply chain systems.

Different Methods Used to Manufacture Industrial Valves

Industrial valves are manufactured in one of two methods: Forging or Casting. It is important to know the differences and discover what type of valve best suits your application.

Forging Method

In this method, solid metals or alloys are shaped under high heat. Various industrial-size tools apply compressive forces on the metals to bend them into the desired designs. Dies cut the material to make specific valves.

The temperature at which this process takes place depends on the type of metal or alloy in use. Since these valves are shaped in one piece, little to no material is wasted by the forging method.

Industrial valves made this way can withstand high levels of pressure and temperature. These valves will have a well-defined grain structure.

Additional Details on the Casting Method

This method employs the use of liquid metal to make valves. The raw metal is subjected to high temperatures, where it melts into a molten liquid. The molten liquid is then poured into molds. After cooling and solidifying, the cast is removed from the mold.

Casting gives the potential to make valves of all designs, shapes, sizes and patterns. You can also make valves using a combination of metals or alloys.

|

Forging Method |

Casting Method |

|

Metal or alloy used in solid form. |

Metal or alloy used in molten form. |

|

Only one type of metal or alloy can be used. |

A combination of metals or alloys can be used. |

|

Requires a lot of labor. |

Requires minimal labor. |

|

Limited shapes and designs. |

No limit to shapes, designs, sizes and patterns. |

Conclusion

Industrial valves are indispensable in the supply industry. These valves are often exposed to high temperatures and extreme pressure. It is therefore essential that high-quality materials are used during production. This article sheds light on how these valves are created.

Since they are a mechanical part, valves have a level of engineering to them. There are several factors you should know about how these devices function before you decide to own one. The first is durability. Unlike past technologies, modern valves can be easily repaired or replaced if they fail. This is because they’re made from many components which work together to control water flow.If any piece fails, another one takes its place. You can also buy spare parts at official manufacturers websites for emergencies.

Another concern is longevity. While valve failure is less common than other components in plumbing systems, their ability to withstand pressure and temperature changes is still relatively low.

By being aware of what your valves are capable of, you will know when it's time to replace them. It is always best to avoid emergency repairs as much as possible.

FAQs

-

What metals are used in valve production?

Various metals are used, including cast iron, brass, bronze, special alloy steel and stainless steel. Some commercial valve manufacturers use polymeric composites for their casing parts. These composite items provide many advantages, including low-cost production, excellent dimensional stability, durability, and flexible design options (simply attach one component or blend several components together).

-

What is the lifetime of a valve?

Most valves will remain in perfect working conditions for 10-20 years, or longer.